COMPACK Series

One step shrink wrap machines without tunnel

Technical Specifications:

Max. Capacity:

Max. Roll Diameter:

Working Height (E):

Film Types:

Max. Product Height:

Color:

7-12 pack / min “MC Series”

Ø300mm standard

860mm (8000-i Series 970mm)

POF 7-37micron PVC: 15-25micron

150mm (Optionally Higher)

Light gray RAL7035

Specifications

Max. Film Width:

Installed Power:

Average Consumption:

Chamber Sizes:

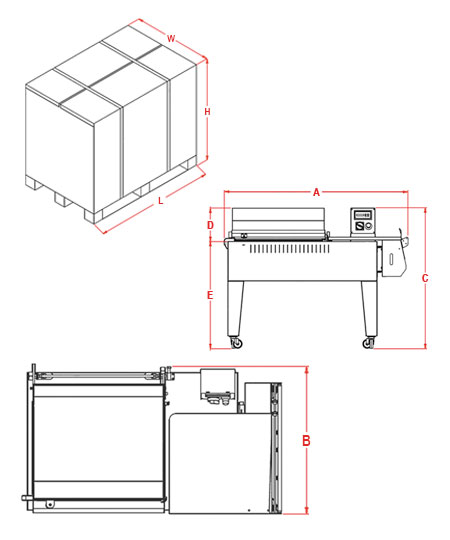

Dimensions (AxBxCxD):

Palletized Size (WxLxH):

Weight (Net / Gross):

Compack 4500-i

400mm

230V 15 Ampere 1 phase

3,4 / 2,1 kW

450 x 300 x 250mm

1080x600x1140x270mm

800 x 1200 x 770mm

100 kg / 130 kg

Compack 5800-i

500mm

230V 19 Ampere 1 phase

4,4 / 2,6 kW

580 x 440 x 250mm

1220x730x1140x270mm

800 x 1200 x 770mm

120 kg / 150 kg

Compack 7000-i

600mm

400V 22 Ampere 3 phase

4,9 / 2,9 kW

700 x 510 x 250mm

1480x860x1140x270mm

940 x 1590 x 800mm

151 kg / 205 kg

Compack 8000-i

700mm

400V 27 Ampere 3 phase

6,2 / 3,7 kW

810 x 610 x 250mm

1840x980x1220x270mm

980 x 1930 x 1220mm

176 kg / 224 kg

Compack 5800-MC

500mm

400V 24 Ampere 3 phase

5,2 / 2,8 kW

580 x 440 x 250mm

1575x700x1130x270mm

940 x 1710 x 870mm

143 kg / 177 kg

- Seal & shrink single-step application in the same chamber

- Practical and compact solution for low capacity packaging requirements

- Easily transportable on wheels inside a facility

- Timers and temperature controls by digital control panel

- Magnetic holder keeps the chamber hood closed automatically

- Adjustable perforators for air discharge during shrinkage

Intelligent Sealing System & Advantages:

- Sealing blade power is generated as much as it is needed

- Adaptive temperature power control during variable cycle times

- Start-up power for the sealing blade is controlled with intelligent system.

- Increased duration of composite blade-supports due to efficient heat control

- Sustainable sealing quality and process accuracy by stabilized heat control

Sealing:

- Mechanical switch triggers heating of wire and chamber when the hood is closed

- Sealing is actuated in between wire and silicon rubber by manually closed hood

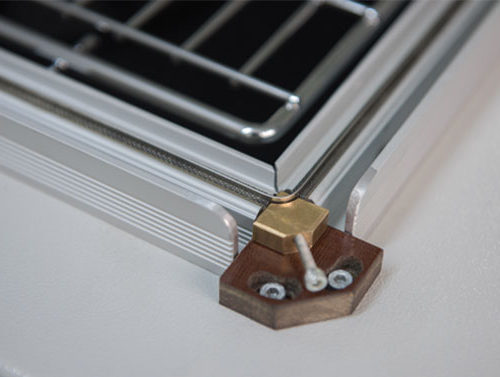

- Teflon belt covered silicon rubber increase sealing quality and life-span of silicon

- Sealing wire is embedded into heat-resistant composite fiber

- Solid state relays in electrical cabinet helps operating long-term and quietly

Flexibility:

- Height adjustable package mesh tray for center sealing option

- Adjustable power of sealing blade against different film thickness

- Poly-bagging option (without shrink) by switching off the fan

- Temperature, timer other options are controlled with digital system

- Various language options are available in digital control panel

- Service menu is available in digital control panel

- Film roll holder with easy to slide, load and align each package

- Working option without pressured air need

- ISO9001 quality standards with the relevant norm’s confirmation

- CE certifications, complies with the latest CE directives

- World-wide approved brands for all mechanical and electrical components

- 1 year warranty for nonwearable parts against manufacturing faults

- 5 years spare part availability