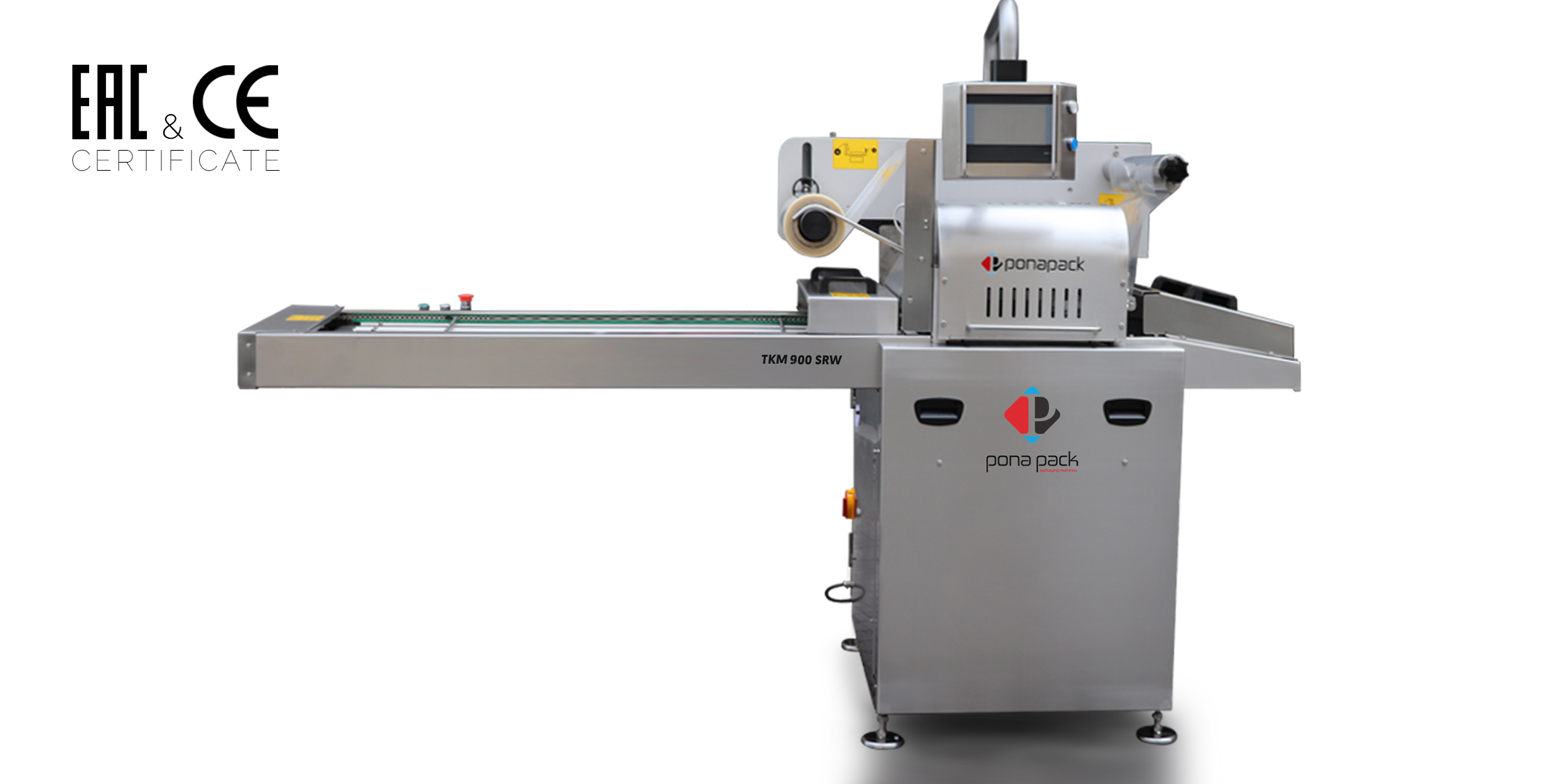

TKM 900 SRW

Automatic Tray Sealer Machine

Specifications:

INSTALLED POWER:

ENERGY CONSUMPTION:

AIR PRESSURE:

AIR CONSUMPTIPON:

CAPACITY/MIN:

MACHINE DIMENSION:

MAX. MOLD DIMENSIONS:

WEIGHT NET/PACKAGED:

MAX. PLATE DEPTH:

MAX. FILM WIDTH:

MIN. FILM THICKNESS:

INFEED BAND:

DISCHARGE BELD FREE ROLL:

MAX. FILM WEIGHT

ENERGY CONSUMPTION:

AIR PRESSURE:

AIR CONSUMPTIPON:

CAPACITY/MIN:

MACHINE DIMENSION:

MAX. MOLD DIMENSIONS:

WEIGHT NET/PACKAGED:

MAX. PLATE DEPTH:

MAX. FILM WIDTH:

MIN. FILM THICKNESS:

INFEED BAND:

DISCHARGE BELD FREE ROLL:

MAX. FILM WEIGHT

380V 50 HZ 40A R.S.T.N.PE

3 KW

MAX. 6 BAR

450 LT CYCLE

10-16 PROCESS

2410 X 1245 X 1565+500 MM STANDARD

670 X 310 MM STANDARD

490 KG

120 MM

670 MM

40 MIC

1500 MM

300 MM

16 KG

Information:3 KW

MAX. 6 BAR

450 LT CYCLE

10-16 PROCESS

2410 X 1245 X 1565+500 MM STANDARD

670 X 310 MM STANDARD

490 KG

120 MM

670 MM

40 MIC

1500 MM

300 MM

16 KG

Completely made of stainless steel. The mold and aluminum parts are eloxal coated. Values can be monitored numerically and graphically with the touch operator panel and any action can be done easily. The pneumatic system is controlled by sensors on the machine and operator is directed by warning message on display. The machine has printed film, non-printed film options and photocell system. Easy to replace mold system provides low mold cost effectiveness, unlimited mold choice and high performance.