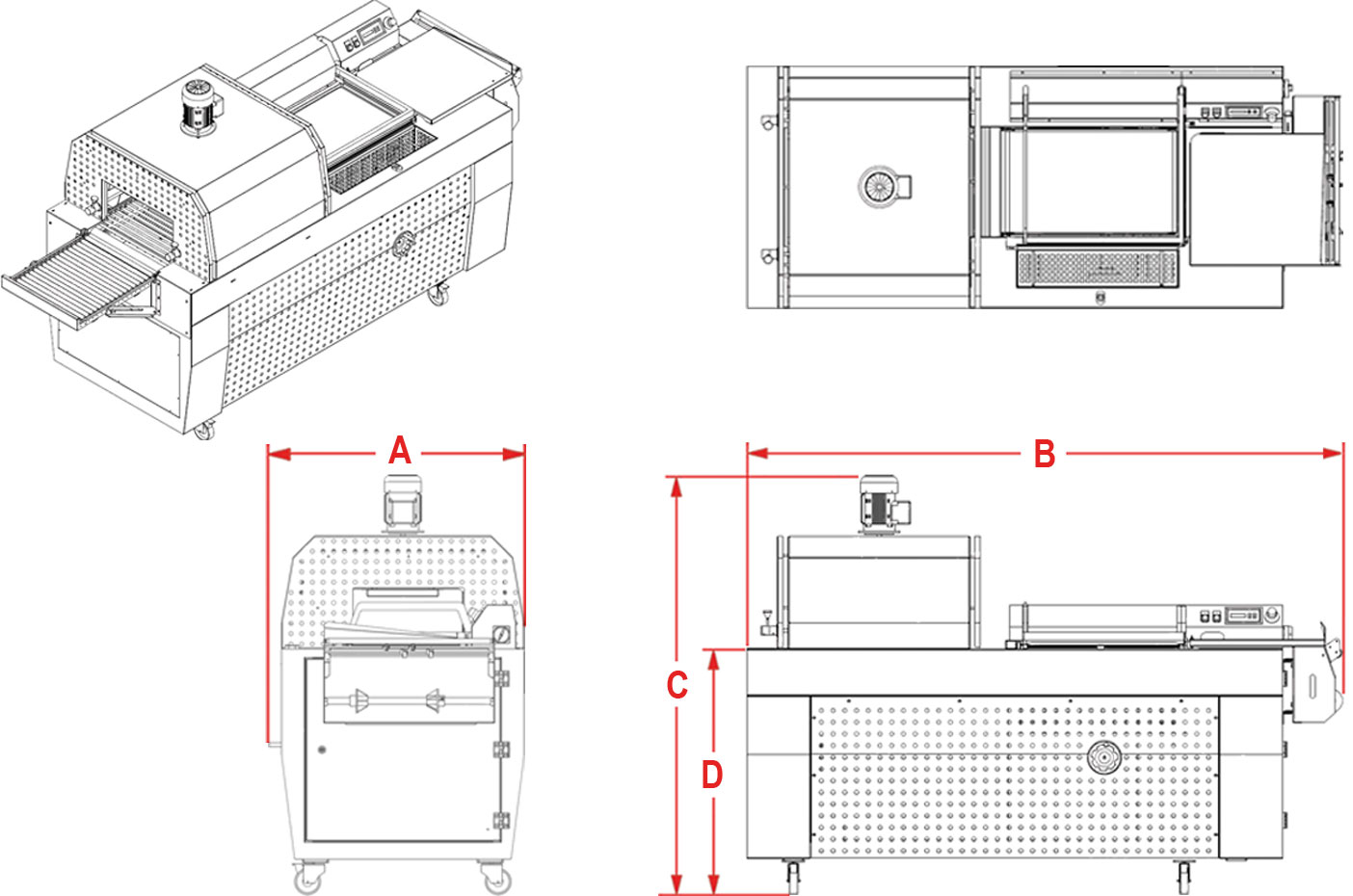

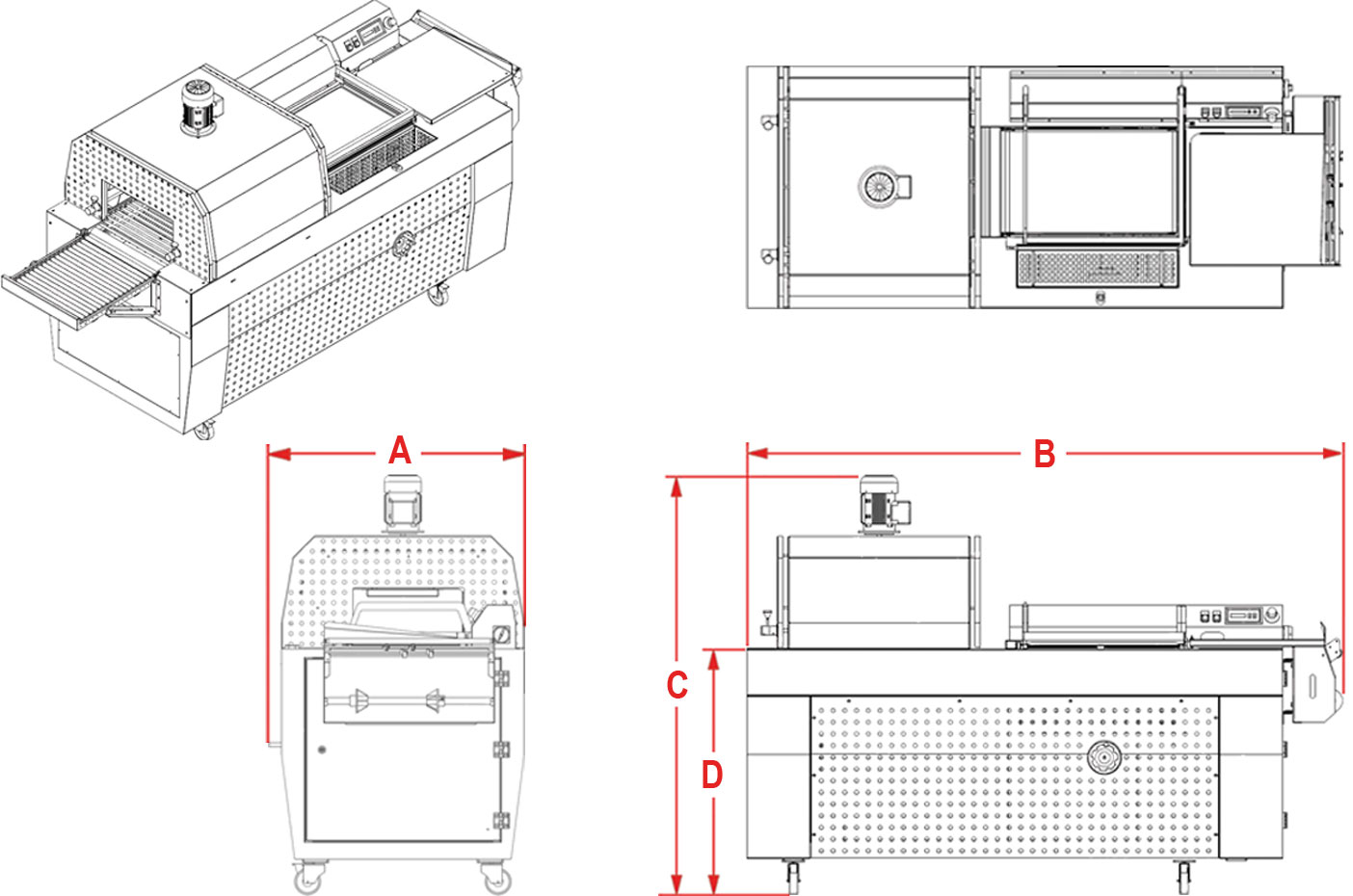

TMC PRO SERIES

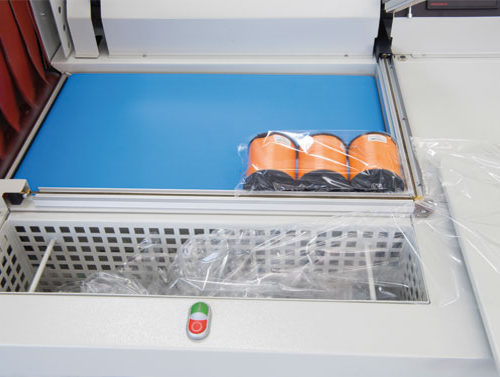

Semi automatic L-sealer and tunnel combination

Technical Specifications:

Sealer Bar Opening:

Maximum Capacity:

Maximum Product Height:

Maximum Roll Diameter:

Working Height (D):

Compr. Air Suplly:

Film Types:

Color:

Maximum Capacity:

Maximum Product Height:

Maximum Roll Diameter:

Working Height (D):

Compr. Air Suplly:

Film Types:

Color:

250mm (10")

10 - 12 packs/minute *

150mm (6")

250mm (10")

960mm (38")

No

POF: 7-37 micron PVC: 15-25 micron

Light gray RAL7035

10 - 12 packs/minute *

150mm (6")

250mm (10")

960mm (38")

No

POF: 7-37 micron PVC: 15-25 micron

Light gray RAL7035

Specifications

Working Principle:

L - Sealer Sizes:

Maximum Film Width:

Installed Power:

Average Consumption:

Dimensions ( AxBxC):

Pallletized Size (AxBxC):

Weight (Net / Gross):

TMC 58x44-H

Close with hand

580 x 440mm (23 x 17")

550mm (22")

400V 13A 3 phase

7,2 kW / 4,2 kW

950 x 2800 x 1600mm (37 x 110 x 63")

1150 x 3000 x 1800mm (45 x 118 x 71")

420 kg / 490 kg (926 lbs / 1080 lbs)

TMC 58x44-M

Motorized

580 x 440mm (23 x 17")

550mm (22")

400V 13A 3 phase

7,2 kW / 4,2 kW

950 x 2800 x 1600mm (37 x 110 x 63")

1150 x 3000 x 1800mm (45 x 118 x 71")

490 kg / 560 kg (1080 lbs / 1235 lbs)

Advantages:

- Minimized layout requirement by compact single-chassis design

- Easy to use, compatible with health and safety standards

- Ability to provide heat to wire at exact efficient dose, realized by I-Sealing System®

- Ability to keep wire temperature constant, realized by I-Sealing System®

- Increase in sealing quality, process accuracy and life-span by stabilized heat control

Features:

- M Series: Sealing L-Bar is driven by a motor (no need for compressed air)

- M Series: In automatic mode, sealing bar cycles automatically in predefined period

- M Series: In free mode, sealing bar is triggered by button

- M Series: Sensor detects any obstacle and stops the cycle automatically for safety

- H Series: Sealing L-Bar is closed by hand, weight is balanced with reverse load

- H Series: Magnetic holder keeps L-Bar closed for pre-defined time period

- Adjustable speed of tunnel conveyor for optimized heat application period

- Heat adjustment with digital PID control

- Air circulation control by side flap handles

- Automatic post cooling system for cooling down to 70ºC before switch off

- Additional emergency temperature control system against fire risk

- Easily transportable on wheels inside a facility

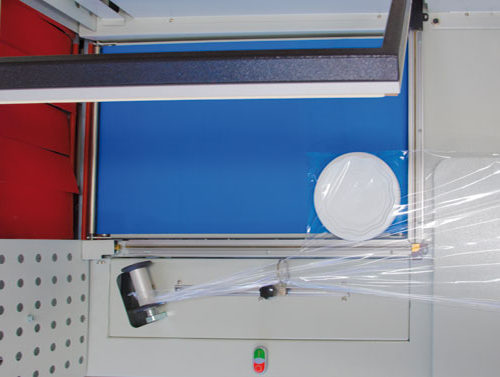

Sealing:

- M Series: Sealing is actuated by motor in between wire and silicon rubber

- H Series: Sealing is actuated manually in between wire and silicon rubber

- Sealing wire is positioned on fixed bottom frame for safety

- Sealing wire is embedded into heat-resistant fiber profile

- Teflon belt covered silicon rubber increase sealing quality and life-span of silicon

Flexibility:

- Height of conveyor line can be adjusted with respect to varying product height

- Working time of conveyor can be adjusted with respect to varying product length

- Power of sealing wire can be adjusted with respect to varying film thicknesses

- Heat, time and speed parameters can be easily adjusted via digital control panel

- Various language options are available in digital control panel

- Minimized layout requirement by compact single-chassis design

- Easy to use, compatible with health and safety standards

- Ability to provide heat to wire at exact efficient dose, realized by I-Sealing System®

- Ability to keep wire temperature constant, realized by I-Sealing System®

- Increase in sealing quality, process accuracy and life-span by stabilized heat control

Features:

- M Series: Sealing L-Bar is driven by a motor (no need for compressed air)

- M Series: In automatic mode, sealing bar cycles automatically in predefined period

- M Series: In free mode, sealing bar is triggered by button

- M Series: Sensor detects any obstacle and stops the cycle automatically for safety

- H Series: Sealing L-Bar is closed by hand, weight is balanced with reverse load

- H Series: Magnetic holder keeps L-Bar closed for pre-defined time period

- Adjustable speed of tunnel conveyor for optimized heat application period

- Heat adjustment with digital PID control

- Air circulation control by side flap handles

- Automatic post cooling system for cooling down to 70ºC before switch off

- Additional emergency temperature control system against fire risk

- Easily transportable on wheels inside a facility

Sealing:

- M Series: Sealing is actuated by motor in between wire and silicon rubber

- H Series: Sealing is actuated manually in between wire and silicon rubber

- Sealing wire is positioned on fixed bottom frame for safety

- Sealing wire is embedded into heat-resistant fiber profile

- Teflon belt covered silicon rubber increase sealing quality and life-span of silicon

Flexibility:

- Height of conveyor line can be adjusted with respect to varying product height

- Working time of conveyor can be adjusted with respect to varying product length

- Power of sealing wire can be adjusted with respect to varying film thicknesses

- Heat, time and speed parameters can be easily adjusted via digital control panel

- Various language options are available in digital control panel

Optional:

- Automatic trim winder option is available upon request

- Stainless steel versions are available for wet/moist working environment

- Speed inverter for air circulation fan of heat tunnel

- Tunnel conveyor alternatives: Wire Mesh, Teflon Mesh or Plastic Mesh

- On-site installation and training service options are available

Quality:

- ISO9001 quality standards with the relevant norm’s confirmation

- CE certifications, complies with the latest CE directives

- World-wide approved brands for all mechanical and electrical components

- 1 year warranty against manufacturing faults

- Wearable parts are not included in warranty terms

- 1 set of wear parts is provided along with the machine

- 5 years spare part stock availability is provided

- Installation, testing and training services are provided free of charge

- Automatic trim winder option is available upon request

- Stainless steel versions are available for wet/moist working environment

- Speed inverter for air circulation fan of heat tunnel

- Tunnel conveyor alternatives: Wire Mesh, Teflon Mesh or Plastic Mesh

- On-site installation and training service options are available

Quality:

- ISO9001 quality standards with the relevant norm’s confirmation

- CE certifications, complies with the latest CE directives

- World-wide approved brands for all mechanical and electrical components

- 1 year warranty against manufacturing faults

- Wearable parts are not included in warranty terms

- 1 set of wear parts is provided along with the machine

- 5 years spare part stock availability is provided

- Installation, testing and training services are provided free of charge