VERIOPACK Pusher Feeder

Vertical packaging systems

Technical Specifications:

Sealer Opening:

Cycle:

L- Sealer Sizes:

Working Height (D):

Collation Conveyor Width:

Cycle:

L- Sealer Sizes:

Working Height (D):

Collation Conveyor Width:

160mm (6")

25 pack/min

770 x 224 mm (30 x 9")

960mm (38")

440mm (17")

25 pack/min

770 x 224 mm (30 x 9")

960mm (38")

440mm (17")

Maximum Film Width:

Film Thickness( Min / Max):

Film Types:

Maximum Roll Diameter:

Color:

800mm (31")

10 - 60 µm

POF, PE, OPP, CPP, PP

Ø300mm (12")

Light gray + RAL7010 + RAL7015

Installed Power:

Average Consumption:

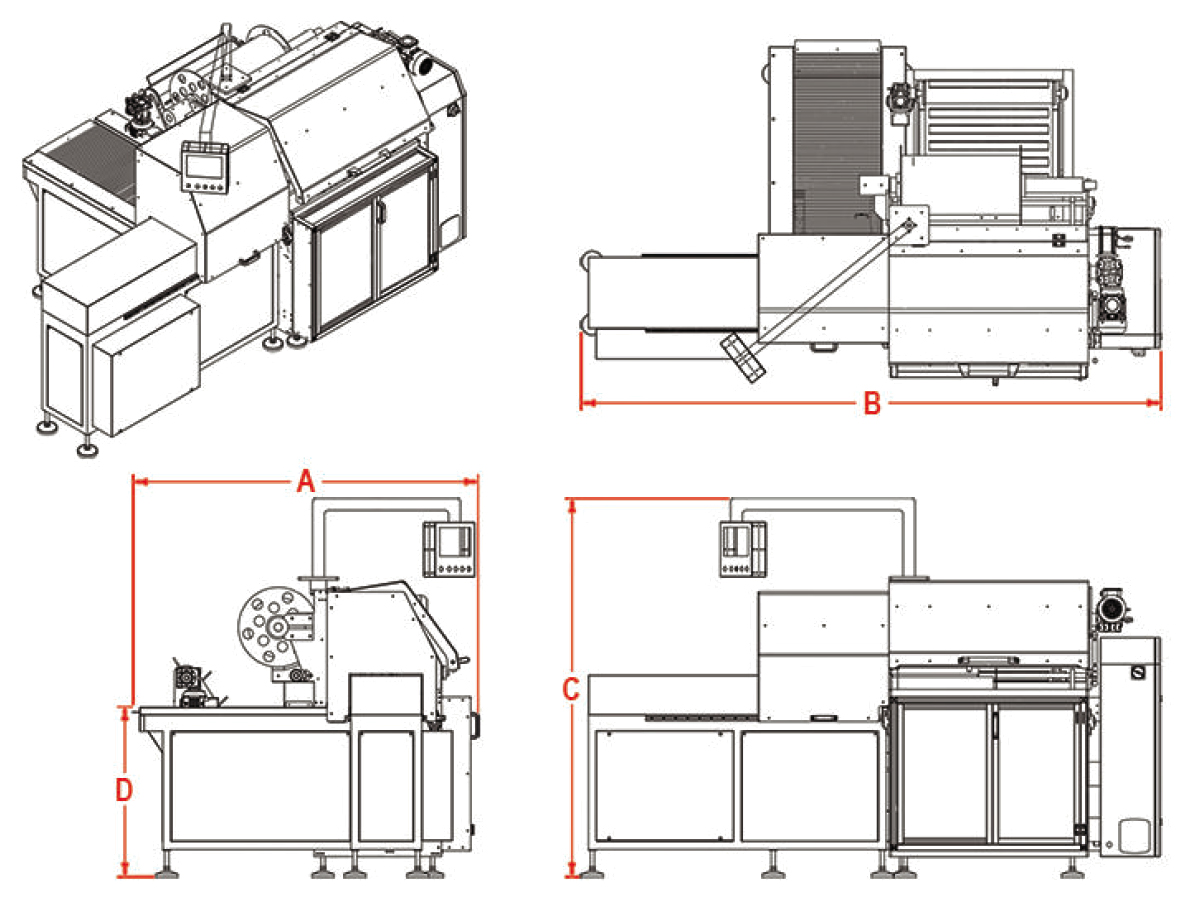

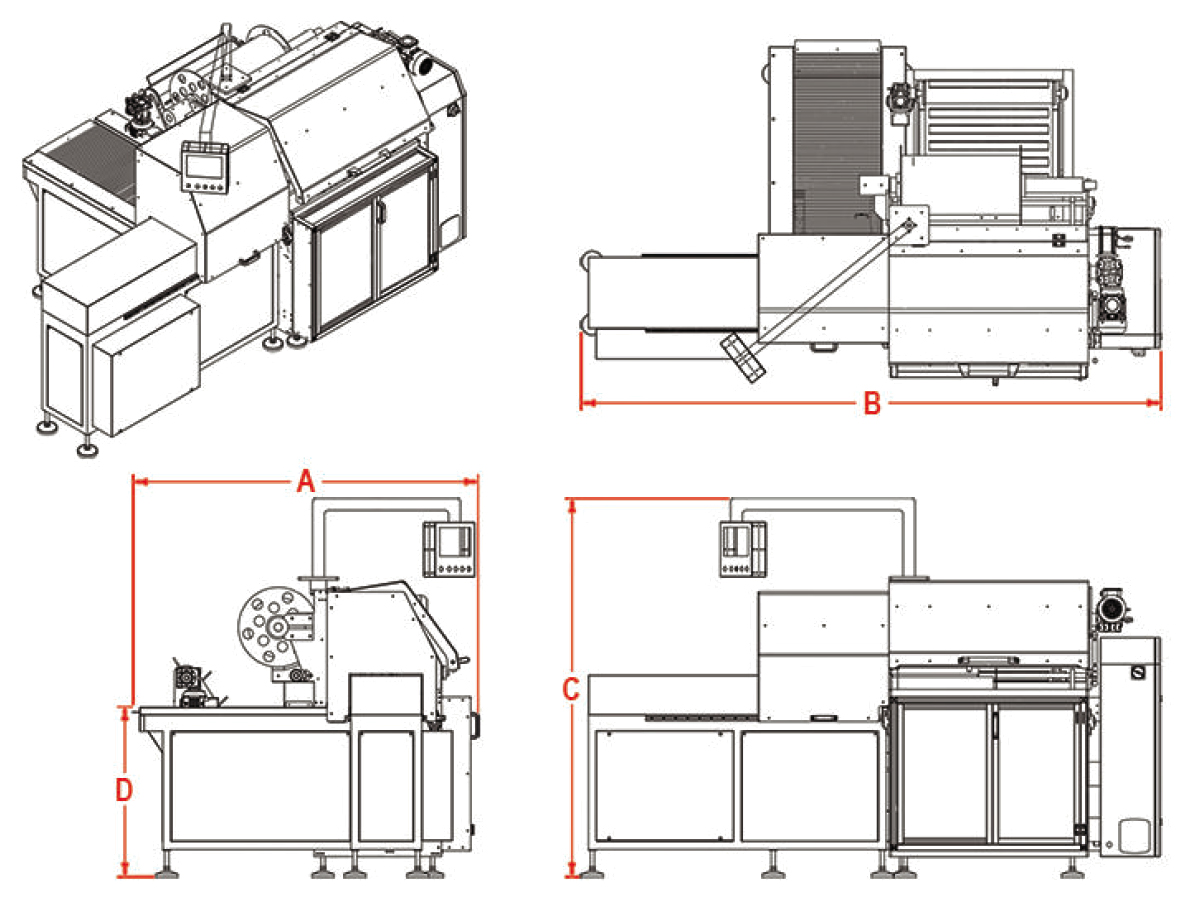

Dimensions (AxBxC):

Palletized Size (AxBxC):

Weight (Net / Gross):

380V, 4 Amper, 3 phase

1Kw - 2Kw

1527 x 1518 x 1506mm (60 x 60 x 59")

1727 x 1718 x 1556mm (68 x 68 x61")

940 kg / 995 kg (2072 lbs / 2194 lbs)

Advantages:

- Very compact and more esthetic new V2 design version

- Precise and fast operation cycle by Servo driven motorized L-bar

- Recordable and re-callable temperature and position adjustments

- Compatible with POF/PE/PP type of packaging materials

- Ability to work with light products by means of film driving winder

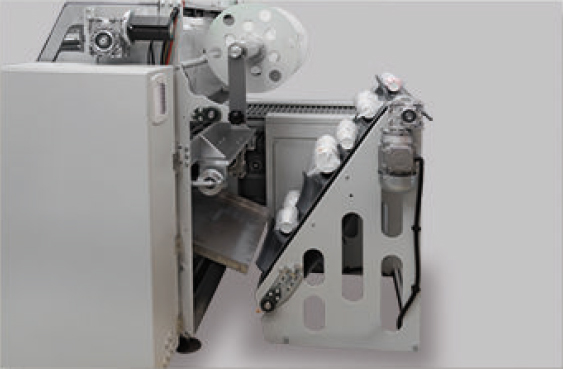

- Easy to access film cradle, accelerated consumed roll changing

Features:

- Easy to integrate with various automatic inline feeding systems

- Integrated discharge conveyor

- Automatic packaging film drive with tension control

- Automatic trim winder with tension control

- Complete housing, accessible windows with safety switches

- User-friendly colorful touch screen movable operator panel

- Feeding frequency control by sensor detection and PLC command

Sealing:

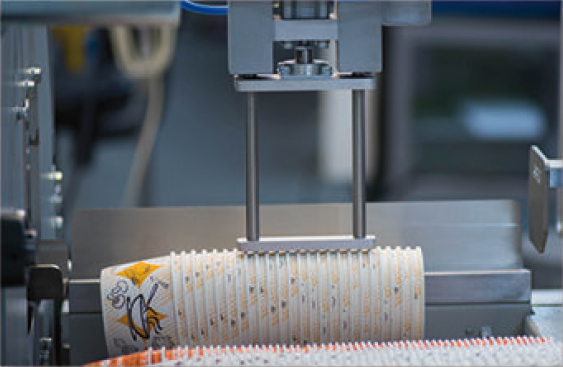

- Adjustable precision and pressure force by Servo driven motor

- PID controlled sealing temperature inserted by touch panel

- Constant temperature L-shape Teflon coated bar sealing system

- L-shape bar length: 770x224mm

Flexibility:

- Easily adjustable for varying product sizes and capacity requirements

- Various language options and adaptable touch keyboard

- Memory Receipt property for prompt adjustments

- Experienced design of sealing blade compatible with broad range of thickness

- Very compact and more esthetic new V2 design version

- Precise and fast operation cycle by Servo driven motorized L-bar

- Recordable and re-callable temperature and position adjustments

- Compatible with POF/PE/PP type of packaging materials

- Ability to work with light products by means of film driving winder

- Easy to access film cradle, accelerated consumed roll changing

Features:

- Easy to integrate with various automatic inline feeding systems

- Integrated discharge conveyor

- Automatic packaging film drive with tension control

- Automatic trim winder with tension control

- Complete housing, accessible windows with safety switches

- User-friendly colorful touch screen movable operator panel

- Feeding frequency control by sensor detection and PLC command

Sealing:

- Adjustable precision and pressure force by Servo driven motor

- PID controlled sealing temperature inserted by touch panel

- Constant temperature L-shape Teflon coated bar sealing system

- L-shape bar length: 770x224mm

Flexibility:

- Easily adjustable for varying product sizes and capacity requirements

- Various language options and adaptable touch keyboard

- Memory Receipt property for prompt adjustments

- Experienced design of sealing blade compatible with broad range of thickness

Optional:

- Printed film applicability by marker detection sensor and programming

- Automatic Feeding System Options:

Horizontal Servo Cup Counter on feeding conveyor

Vertical Counting Tower with stopper flaps

Set of Vertical Towers connected to single transfer conveyor

- Automatic diameter detection and correlated auto-driven film length

- Ability to use single layer flat film by center-folding unit

- Ability to control additional conveyors by inverters

Quality:

- ISO9001 quality standards with the relevant norm’s confirmation

- World-wide approved brands for all mechanical, electrical and pneumatic components

- CE certifications, complies with the latest CE directives

- One year warranty on non-wearable parts (expandable)

- Manufacturer’s guarantee for spare part stock availability up to 5 years at least (expandable)

- Printed film applicability by marker detection sensor and programming

- Automatic Feeding System Options:

Horizontal Servo Cup Counter on feeding conveyor

Vertical Counting Tower with stopper flaps

Set of Vertical Towers connected to single transfer conveyor

- Automatic diameter detection and correlated auto-driven film length

- Ability to use single layer flat film by center-folding unit

- Ability to control additional conveyors by inverters

Quality:

- ISO9001 quality standards with the relevant norm’s confirmation

- World-wide approved brands for all mechanical, electrical and pneumatic components

- CE certifications, complies with the latest CE directives

- One year warranty on non-wearable parts (expandable)

- Manufacturer’s guarantee for spare part stock availability up to 5 years at least (expandable)