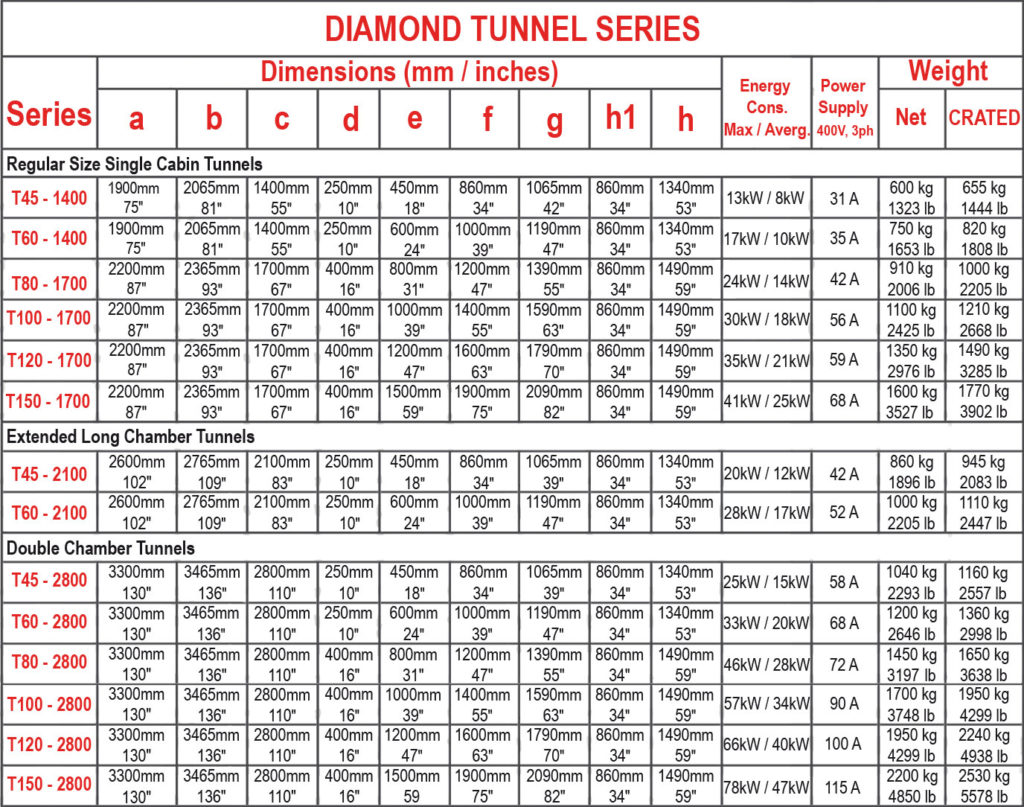

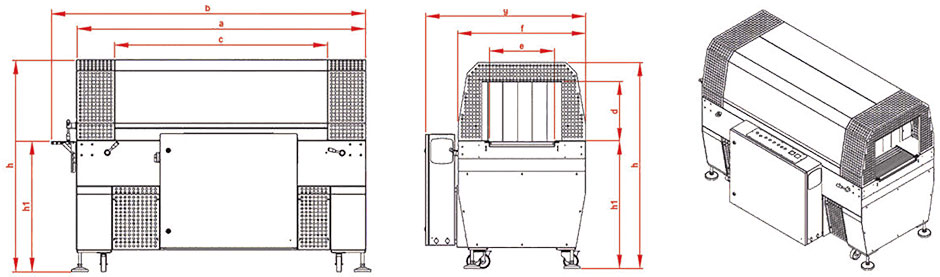

Diamond Heat Tunnels

High performance bottom circulated shrink tunnels

Features:

- Reduced energy consumption by double layered isolation room

- Bottom embedded heat chamber and fan system

- Perfectly dissipated heat inside via adjustable flaps and channels

- Conveying speed control to optimize heat treatment duration

- Instant switching from PE to POF by chain lift-up system (T45 & T60 only)

- Automatic cool down to 70ºC before switch off

- Easy to integrate with all types of packaging machines directly

- Equipped with caster wheels & brakes, easy to re-position in facility

- PID controlled accurate heat adjustment

- Circulation fan speed control to optimize air flow rate

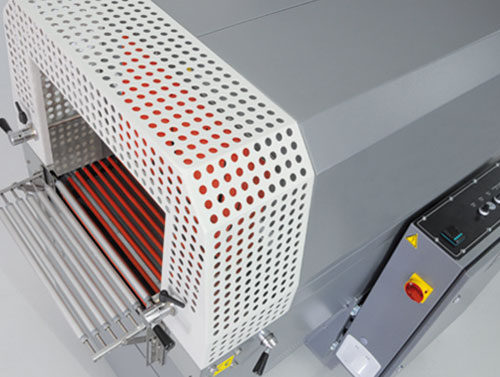

- Long lasting covered tunnel conveyor spindles

- Color: Metallic Dark Gray (RAL Code: Customized Mixture)

- Alternative conveyor types: Wire Mesh, Teflon Mesh, Plastic Mesh

- Higher chamber and frame designs are available

- Ironing Rollers at discharge for side smoothing of PE wrapped package

- PE Cooling Fan at discharge for fast cool-down of PE wrapped package

- Exhaust gas hood can be applied if required by application

- Stainless steel versions are available for wet/moist working environment

- Recordable heat and speed via touch panel controller

- At the infeed and discharge points of the tunnels metal protection shields are applied to avoid human contact to high temperature surfaces.

- Conveyors stop automatically during jams to avoid further problems.

- Against high temperature or fire risk, in case of the stop of the conveyor or fan circulation, the heaters are isolated automatically.

-Tunnel fan have been protected with mesh guards and operator hands can not be contacted.