IMPACK ProMotion

Continuous motion high speed side sealer

Technical specifications:

Max. Speed:

Max. Cycle:

Max. Roll Diameter:

Working Height:

Air Supply:

Color:

30mt/min

110 packs/min*

Ø 270mm (11")

860mm (+50mm) (34")

7-40 µm PO, PP “ V ” Knife

40-80 µm PE, OPP “ W ” Knife

Mixed grey + RAL7010 + RAL7015

Specifications

Cross Sealer Length:

Conveyor Belt Width:

Max. Film Width:

Installed Power:

Average Consump.:

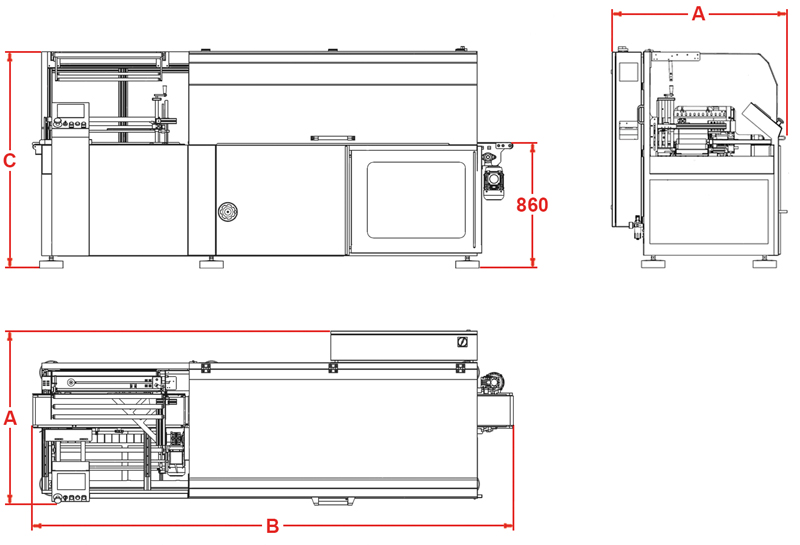

Dimens. (AxBxC):

Palletized Size (AxBxC):

Weight (Net / Gross):

Impack ProMotion 20

400mm (16")

200mm (8")

700mm AC(28")

400V-3Ph, 8A, 6 kW

3kW

1350x3250x1480mm (53x128x58")

1500x3450x1650mm (59x136x65")

700 / 790 kg (1543 / 1742 lbs)

Impack ProMotion 40

540mm (21")

400mm (16")

700mm (28")

400V-3Ph, 9A, 6,8kW

4kW

1500x3250x1480mm (59x128x58")

1700x3450x1650mm (67x136x65")

980 / 1010 kg (2161 / 2227 lbs)

Impack ProMotion 60

730mm (29")

600mm (24")

1000mm (39")

400V-3Ph, 9A, 7,2kW

5kW

1800x3750x1600mm (71x148x63")

2000x3950x1700mm (79x156x67")

1090 / 1250 kg (2403 / 2756 lbs)

Impack ProMotion 80

930mm (37")

800mm (31")

1000mm (39")

400V-3Ph, 10A, 7,5kW

5,5kW

2000x3750x1600mm (79x148x63")

2200x3950x1700mm (87x156x67")

1140 / 1320 kg (2513 / 2910 lbs)

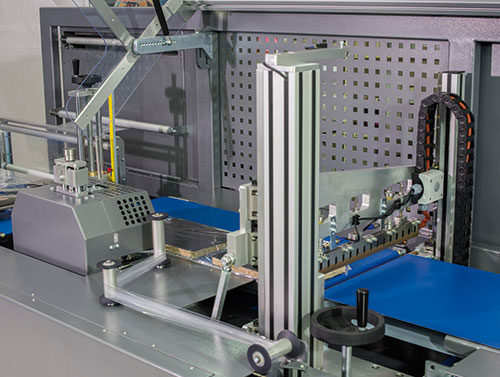

- Nonstop operation with continuous motion system

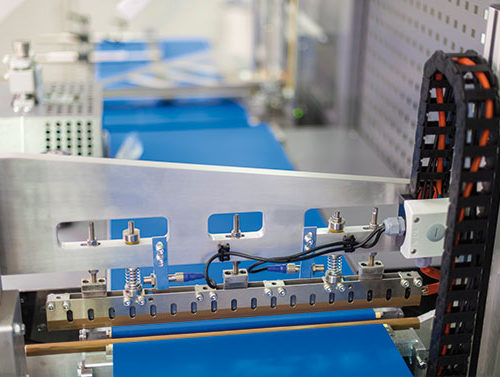

- Dual axis servo motor driven cross sealing

- High precision and consistency with cross and side seal

- Packaging with no length limit

- Control of film quantity on the 4 sides of packages for saving results

- Minimized layout requirement by compact single-chassis design

- Reduced energy & increased safety

Features:

- Touch control panel with color screen

- Encoder controlled speed & length aware synchronization

- Easy format change for different package sizes

- Regular or finger pitch conveyors for feeding can be applied

- Ergonomic operator panel with most useful hard buttons

- Up-to-date safety electic and mechanic measures of CE directives

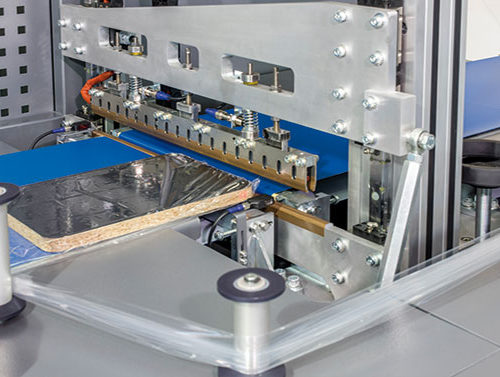

- Cross and continuous knives with PID controlled heaters

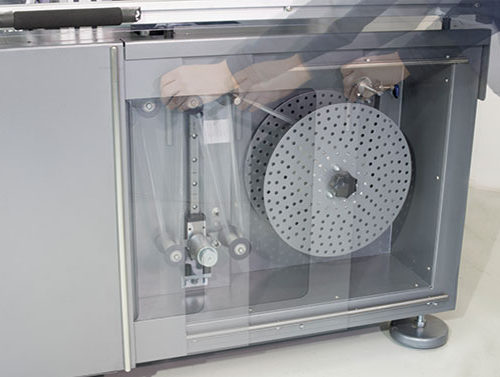

- Automatic film dispenser with tension control

- Photocell controlled package distance positioned feeding

- Automatic length detection option

Sealing:

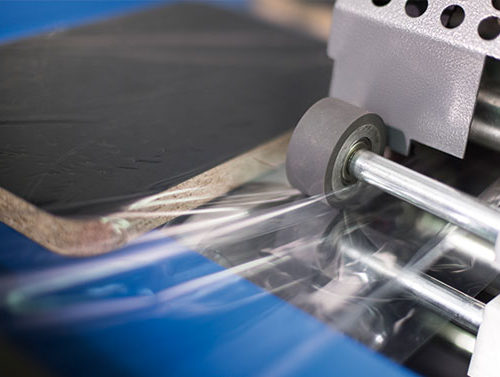

- Film sealing under no distortion with non stop and tight operation

- Up to 15% advantage in film consumption

- Film tension releasing on the cross-sealing point

- Trim winder is designed to control very thin films without breakage

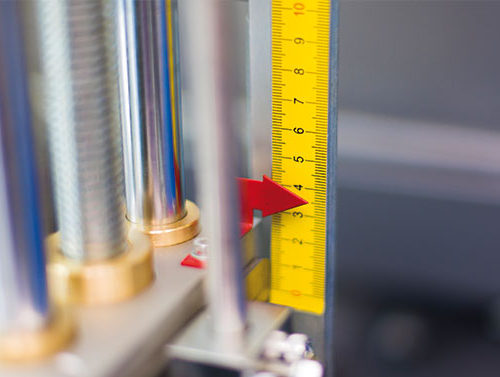

- Height adjustable cross sealer (Optional motorized)

- Adjustable “Central Sealing” for varied package height applications

Flexibility:

- Native languages can be applied

- Recipe application with different package dimensions

- Warning messages for potential emergency cases

- "Navigation Control” for actual throughput and estimated packs/time units

- Double seal feature on cross sealer for high thickness or PE material

- Control of external infeed conveyor through operator panel

- Vertical photocell to detect thin packages

- Printed marker registered film detection & application

Quality:

- ISO 9001 quality standard with the relevant norm’s confirmations

- CE marking

- One year warranty on non-wearable parts

- Manufacturer’s guarantee for spare part & after sales support