SYMPACK complete solution

Fully automated continuous sealer and tunnel combination

Advantages:- Minimized layout requirement by compact and esthetic single-chassis design

- The optimum automatic solution for above average capacity processes

- Continuous side sealer provides unlimited length packaging ability

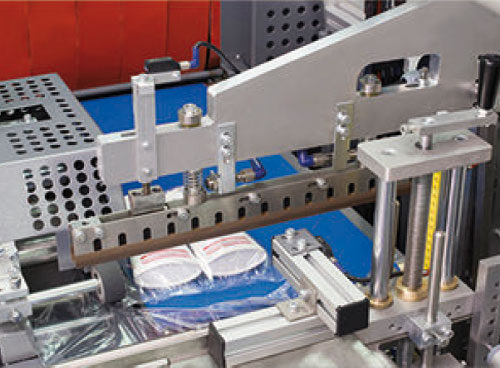

- Very fast and flawless sealing property by Servo driven vertical sealer

- Easy to integrate with the production lines directly

- Recordable and re-callable temperature and position adjustments

Technical Specifications:

Maximum Packaging Size:

Sealer Opening:

Conveyor Speed:

Cross Sealer Length:

Working Height:

Conveyor Belt Width:

Minimum Package Width:

Maximum Film Width:

Film Thickness:

W:650 L:300 H:200mm (26x12x8")

200mm (8")

0-30 mt/min. (adjustment)

420mm (17")

855mm (+50mm) (34")

350mm (14")

50mm (2")

550mm (22")

15-60 micron

Film Types:

Maximum Roll Diameter:

Color:

Air Supply:

Installed Power:

Average Consumption:

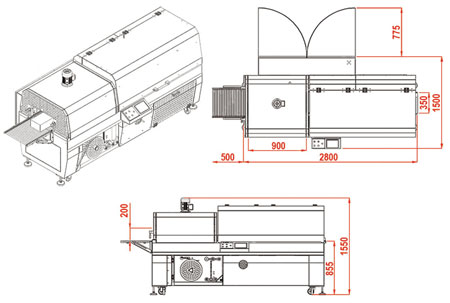

Dimensions (Width/Lenght/Height):

Palletized Size (Width/Lenght/Height):

Weight (Net / Gross):

POF, PE, PVC

Ø 270mm (11")

Mixed grey + RAL7015 + RAL7010

6 Bar

400v - 3 phase, 20A, 13kW

8 - 10 kW

1500x28001550mm (59x110x61")

1700x3000x1750mm (67x118x69")

690 kg / 810 kg (1521 lbs / 1786 lbs)

Features:

- Automatic length detection by sensor synchronized with encoder control

- User-friendly colorful touch screen operator panel

- Automatic packaging film drive with tension control

- Automatic trim winder with tension control

- Automatic post cooling mechanism for cooling down to 70ºC before switch off

- Additional emergency temperature control system against fire risk

- Feeding frequency control by sensor detection and PLC command

- Ability to read instant (or total) realized capacity by counter

- Strong needle-wheel frame structure for air discharge perforation

- Reduced energy consumption and increased esthetic look by Diamond design

- Adjustable speed of tunnel conveyor for optimized heat application period

- Heat adjustment with digital PID control

- Air circulation control by side flap handles

Sealing:

- Center-Seal property provides accurate and linear sealing line

- Adjustable precision and pressure on cutting and sealing force

- PID controlled sealing temperature inserted by touch panel

- Alternative sealing blade structures for various packaging material

- Product clearance control under seal bar by sensor

Flexibility:

- Easily adjustable for varying product sizes and capacity requirements

- Various language options and adaptable touch keyboard

- Memory Receipt property for prompt adjustments

- Experienced design of sealing blade compatible with broad range of thickness

- User friendly designed trim-winder for easy and prompt trim unloading

- Less layout space requirement by embedded easy-to-open film roll drawer

Optional:

- Solenoid actuator for side sealer: Free of compressed air requirement

- Ability to control additional conveyors by inverters

- Chain lift-up system to easily switch in between PE/POF material

- Tunnel conveyor alternatives: Wire Mesh, Teflon Mesh or Plastic Mesh

Quality:

- ISO9001 quality standards with the relevant norm’s confirmation

- World-wide brands for all mechanical, electrical and pneumatic components

- CE certifications, complies with the latest CE directives

- One year warranty on non-wearable parts (extendable)

- Manufacturer’s guarantee for spare part stock and after sales support

- Manufacturer’s guarantee for spare part stock availability up to 5 years

- Automatic length detection by sensor synchronized with encoder control

- User-friendly colorful touch screen operator panel

- Automatic packaging film drive with tension control

- Automatic trim winder with tension control

- Automatic post cooling mechanism for cooling down to 70ºC before switch off

- Additional emergency temperature control system against fire risk

- Feeding frequency control by sensor detection and PLC command

- Ability to read instant (or total) realized capacity by counter

- Strong needle-wheel frame structure for air discharge perforation

- Reduced energy consumption and increased esthetic look by Diamond design

- Adjustable speed of tunnel conveyor for optimized heat application period

- Heat adjustment with digital PID control

- Air circulation control by side flap handles

Sealing:

- Center-Seal property provides accurate and linear sealing line

- Adjustable precision and pressure on cutting and sealing force

- PID controlled sealing temperature inserted by touch panel

- Alternative sealing blade structures for various packaging material

- Product clearance control under seal bar by sensor

Flexibility:

- Easily adjustable for varying product sizes and capacity requirements

- Various language options and adaptable touch keyboard

- Memory Receipt property for prompt adjustments

- Experienced design of sealing blade compatible with broad range of thickness

- User friendly designed trim-winder for easy and prompt trim unloading

- Less layout space requirement by embedded easy-to-open film roll drawer

Optional:

- Solenoid actuator for side sealer: Free of compressed air requirement

- Ability to control additional conveyors by inverters

- Chain lift-up system to easily switch in between PE/POF material

- Tunnel conveyor alternatives: Wire Mesh, Teflon Mesh or Plastic Mesh

Quality:

- ISO9001 quality standards with the relevant norm’s confirmation

- World-wide brands for all mechanical, electrical and pneumatic components

- CE certifications, complies with the latest CE directives

- One year warranty on non-wearable parts (extendable)

- Manufacturer’s guarantee for spare part stock and after sales support

- Manufacturer’s guarantee for spare part stock availability up to 5 years