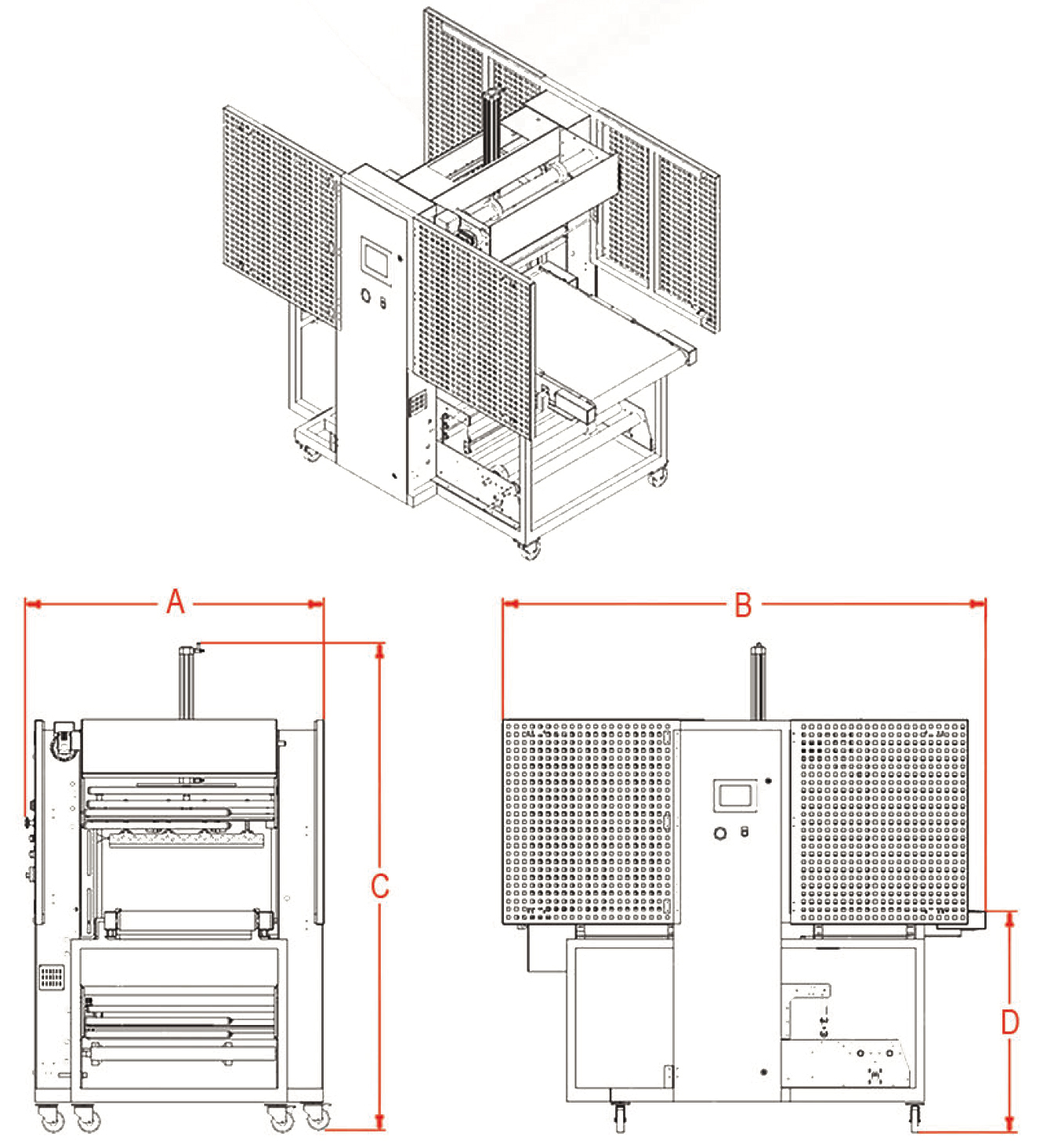

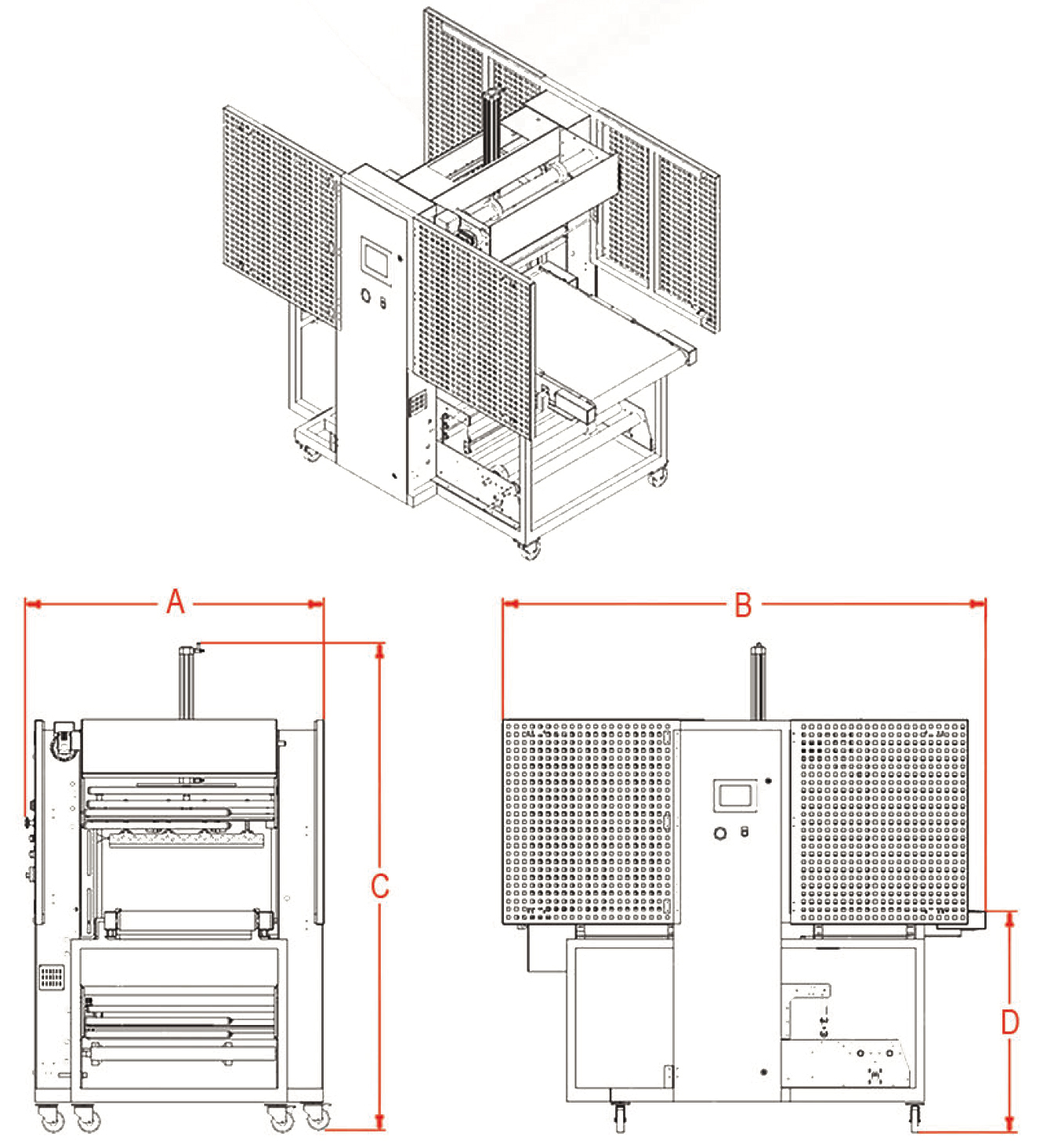

“PE-D” Series

Fully automated PE wrapper machines

Specifications:

Sealer Bar Opening:

Max. Cow. Speed:

Max. Cycle:

Max. Roll Diameter:

Working Height (D):

Compr. Air Supply:

Film Types: PE:

Color:

Max. Cow. Speed:

Max. Cycle:

Max. Roll Diameter:

Working Height (D):

Compr. Air Supply:

Film Types: PE:

Color:

400mm

20 mt./min (adjustable)

20 cycle/min

350mm (adjustable)

860 - 960mm

6-7 bar

PE: 30-80my

Mixed grey RAL7015, RAL7010

20 mt./min (adjustable)

20 cycle/min

350mm (adjustable)

860 - 960mm

6-7 bar

PE: 30-80my

Mixed grey RAL7015, RAL7010

Specifications:

Cross Sealer Length:

Conveyor Belt Width:

Max. Film Width:

Installed Power:

Average Comsumpfion:

Dimensions (AxBxC):

Palletized Size (AxBxC):

Weight (Net/Gross):

PE 60D

680mm

600mm

600mm

5 Amper

3kW

1300x2000x2200mm

1500x22002400mm

350kg/450kg

PE 80D

840mm

800mm

800mm

6 Amper

3kW

1500x2000x2200mm

1700x22002400mm

450kg/570kg

PE 100D

1050mm

1000mm

1000mm

7 Amper

3,8kW

1650x2000x2200mm

1850x22002400mm

550kg/690kg

PE 120D

1240mm

1200mm

1200mm

8 Amper

4,2kW

1800x2000x2200mm

2000x2200x2400mm

650kg/810kg

PE 150D

1540mm

1500mm

1500mm

9 Amper

4,2kW

1800x2000x2200mm

2400x2200x2400mm

750kg/930kg

Advantages:

- Customized design and strengthened mechanic properties for high products

- Easy to integrate with the production lines directly

- Portable mono-block chassis on caster wheels with brakes - Recordable and re-callable temperature adjustments

Features:

- Fully automatic system with motorized inlet/discharge belt conveyors

- Automatic length detection by sensor synchronized with encoder control

- Feeding frequency control by sensor detection and PLC command

- User-friendly colorful touch screen operator panel

- Excellent balancing of sealing blade on conjugated linear bearings

- Auto PE film driving motorized rollers triggered by suspension arm - Ability to read instant (or total) realized capacity by counter

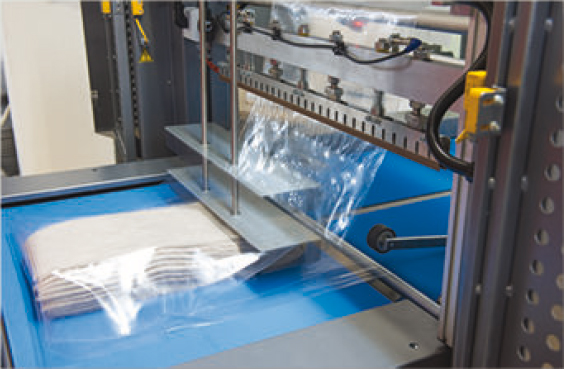

Sealing:

- Teflon coated hot sealing knife embedded in visor protected top sealer

- Teflon belt covered & heat-proof silicon bed embedded bottom sealer

- PID controlled sealing temperature inserted by touch panel

- Ability to work with wide range of film thicknesses - Product clearance control under seal bar by sensor

Flexibility:

- Easily adjustable for varying product sizes and capacity requirements

- Various language options and adaptable touch keyboard

- Memory Receipt property for prompt adjustments

- Experienced design of sealing blade compatible with broad range of thickness

- Customized design and strengthened mechanic properties for high products

- Easy to integrate with the production lines directly

- Portable mono-block chassis on caster wheels with brakes - Recordable and re-callable temperature adjustments

Features:

- Fully automatic system with motorized inlet/discharge belt conveyors

- Automatic length detection by sensor synchronized with encoder control

- Feeding frequency control by sensor detection and PLC command

- User-friendly colorful touch screen operator panel

- Excellent balancing of sealing blade on conjugated linear bearings

- Auto PE film driving motorized rollers triggered by suspension arm - Ability to read instant (or total) realized capacity by counter

Sealing:

- Teflon coated hot sealing knife embedded in visor protected top sealer

- Teflon belt covered & heat-proof silicon bed embedded bottom sealer

- PID controlled sealing temperature inserted by touch panel

- Ability to work with wide range of film thicknesses - Product clearance control under seal bar by sensor

Flexibility:

- Easily adjustable for varying product sizes and capacity requirements

- Various language options and adaptable touch keyboard

- Memory Receipt property for prompt adjustments

- Experienced design of sealing blade compatible with broad range of thickness

Optional:

- Printed film applicability by marker detection sensor and programming

- Fully controlled easy film drive mechanism for both top and bottom PE rolls

- Repositioning of top and bottom PE film roll nests to waist level

- Spare roll nests and manual film splicing unit

- Ability to control additional conveyors by inverters

- Ability to stabilize and pressurize unsteady products by top-pressure cylinder

- Enhanced pressure and position control of vertical sealer by Servo motor - Linking conveyor: Non-rigid, wavy-based or short products (L < 15cm)

Quality:

- IS09001 quality standards with the relevant norm's confirmation

- World-wide brands for all mechanical, electrical and pneumatic components

- CE certifications, complies with the latest CE directives

- One year warranty on non-wearable parts (expandable)

- Manufacturer's guarantee for spare part stock and after sales support

- Manufacturer's guarantee for spare part stock availability up to 5 years

- Printed film applicability by marker detection sensor and programming

- Fully controlled easy film drive mechanism for both top and bottom PE rolls

- Repositioning of top and bottom PE film roll nests to waist level

- Spare roll nests and manual film splicing unit

- Ability to control additional conveyors by inverters

- Ability to stabilize and pressurize unsteady products by top-pressure cylinder

- Enhanced pressure and position control of vertical sealer by Servo motor - Linking conveyor: Non-rigid, wavy-based or short products (L < 15cm)

Quality:

- IS09001 quality standards with the relevant norm's confirmation

- World-wide brands for all mechanical, electrical and pneumatic components

- CE certifications, complies with the latest CE directives

- One year warranty on non-wearable parts (expandable)

- Manufacturer's guarantee for spare part stock and after sales support

- Manufacturer's guarantee for spare part stock availability up to 5 years