IMPACK PRO Series

Fully automated continuous sealer packaging machine

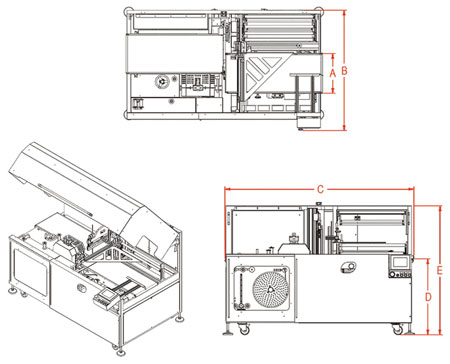

Technical Specifications:

Max. Conv. Speed:

Max. Cycle:

Max. Roll Diameter:

Working Height (D):

Film Types:

Color:

30 mt/min (adjustable)

60 cycle/min (example:DIN A4 form)

300mm standard (adjustable)

860mm

7-40 µm PO, PP “ V ” Knife

40-80 µm PE, OPP “ W ” Knife

Customised,(Mixed grey + RAL7015 + RAL7010)

Specifications:

Cross Sealer Length:

Conveyor Belt Width (A):

Max. Film Width:

Installed Power:

Average Comsumption:

Dimensions (BxCxE):

Palletized Size (BxCxE):

Weight (Net / Gross):

Impack Pro 20

300mm

200mm

650mm

400V 5 Amper 3 Faz

Maks: 3,7Kw average 1,9Kw

1250x2320x1600mm

1020x2120x1500mm

624 kg / 690 kg

Impack Pro 40

530mm

400mm

650mm

400V, 6 Ampere 3 phase

Max: 3,7Kw, ort. 1,9Kw

1270x2120x1500mm (50x83x59")

1470x2320x1600mm (58x91x63")

780 kg / 860 kg (1720 lbs / 1896 lbs)

Impack Pro 60

920mm

600mm

1000mm

400V, 6 Ampere 3 phase

Max: 6Kw, ort. 3Kw

1930 x 2640 x 2000mm (76 x 104 x 79")

2130 x 2955 x 1750 (84 x 116 x 69")

1050 kg / 1170 kg (2315 lbs / 2579 lbs)

Specifications:

Cross Sealer Length:

Conveyor Belt Width (A):

Max. Film Width:

Installed Power:

Average Comsumption:

Dimensions (BxCxE):

Palletized Size (BxCxE):

Weight (Net / Gross):

Impack Pro 80

920mm

800mm

1000mm

400V, 7 Ampere 3 phase

Max: 3,7Kw, ort. 1,9Kw

1600x2700x1500mm (63x106x59")

1800x2900x1600mm (71x114x63")

1410 kg / 1550 kg (3109 lbs / 3417 lbs)

Impack Pro 100

920mm

1000mm

1250mm

400V, 8 Ampere 3 phase

Max: 7Kw, ort. 4Kw

2530 x 2640 x 2000mm (100 x 107 x 79")

2730 x 2955 x 1750mm (107 x 116 x 69")

1960 kg / 2180 kg (4321 lbs / 4806 lbs)

- Very compact and new esthetic ‘Pro’ design

- Continuous side sealer provides unlimited length packaging ability

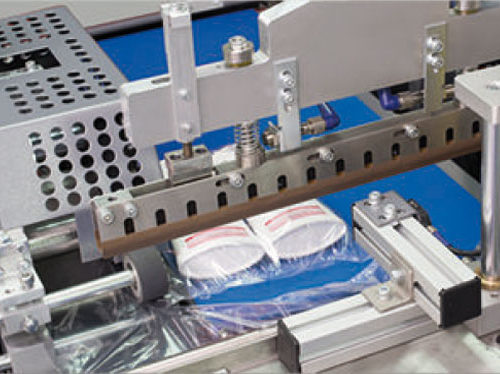

- Very fast and flawless sealing property by Servo driven vertical sealer

- Easy to integrate with the production lines directly

- Recordable and re-callable package parameter settings

Features:

- Automatic length detection by sensor synchronized encoder control

- User-friendly color touch screen operator panel

- Automatic packaging film drive with tension control

- Automatic trim winder with tension control

- Feeding frequency control by sensor detection and PLC control

Sealing:

- Center-Seal property provides accurate and linear sealing line

- Adjustable precision and pressure on cutting and sealing force

- PID controlled sealing temperature inserted by touch panel

- Alternative sealing blade structures for various packaging material

- Product clearance control under seal bar by sensor

Flexibility:

- Easily adjustable wrt. varying product sizes and capacity

- Various language options and adaptable touch keyboard

- Memory Receipt property for prompt adjustments

- Perfect sealing blade design compatible with varying thicknesses

- Solenoid actuator for side sealer: Free of compressed air requirement

- Printed film applicability by marker detection sensor and programming

- Center folder system for single layer flat film applicaiton

- Ability to control additional conveyors by inverters

- Linking Belt (3 bar compressed air is require)

Quality:

- ISO9001 quality standards with the relevant norm’s confirmation

- World-wide brands for all mechanical, electrical and pneumatic components

- CE certifications, complies with the latest CE directives

- One year warranty on non-wearable parts (extendable)

- Manufacturer’s guarantee for spare part stock and after sales support

- Manufacturer’s guarantee for spare part stock availability up to 5 years