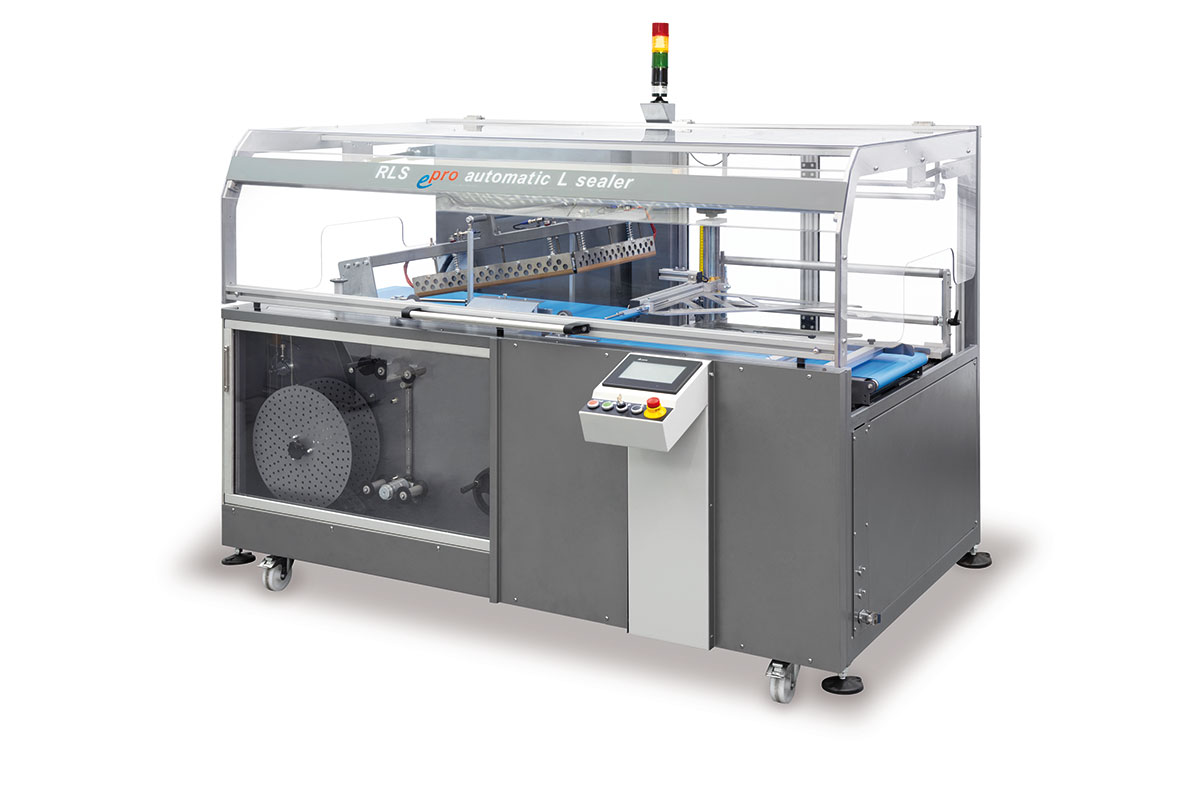

RLS ePro Series

Electric servo driven L sealer packaging machine

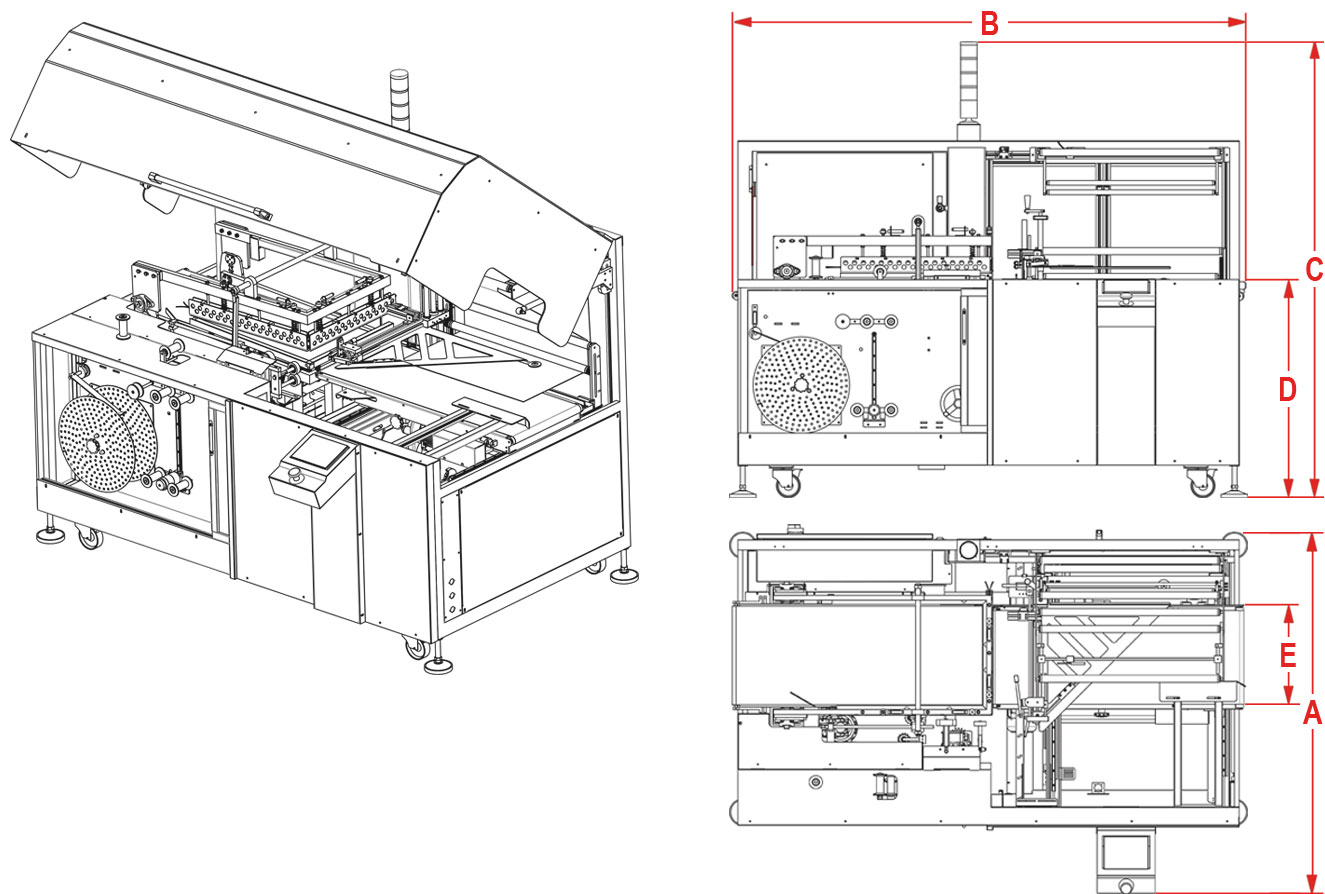

Technical Specifications:

Maximum Packaging Sizes:

Sealer Opening:

Conveyor Speed:

Cross Sealer Lenght:

Working Height (D):

Conveyor Belt Width (E):

Sealer Opening:

Conveyor Speed:

Cross Sealer Lenght:

Working Height (D):

Conveyor Belt Width (E):

E:350 x B:450 x Y:160 mm

160mm

30 mt/dk (adjustable)

580 x 440mm

860mm

400mm

160mm

30 mt/dk (adjustable)

580 x 440mm

860mm

400mm

Minimum Package Width:

Maximum Film Width:

Film Thickness (Min / Max):

Film Types:

Maximum Roll Diameter:

Color:

50mm

650mm

10 - 80 micron *

POF, PE, OPP, CPP, PP

300mm standard (adjustable)

Gray mixed + RAL7010 + RAL7015

Compressed Air:

Installed Power:

Consumption:

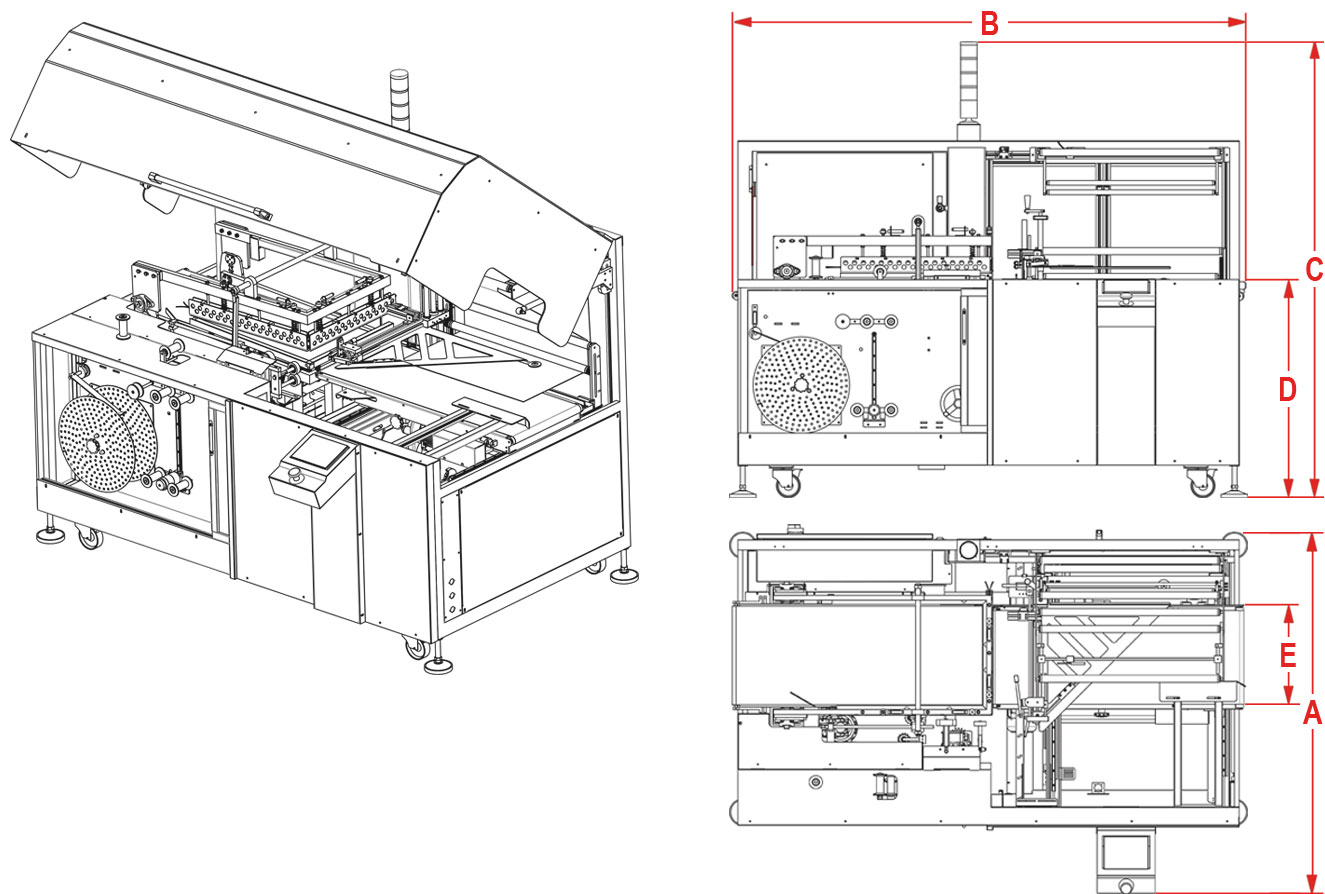

Dimensions (AxBxC):

Palletized Size (AxBxC):

Weight (Net / Gross):

No need *

400V, 6 Ampere, 3 Fase

Max: 3,7Kw, avarage: 1,9Kw

1480x2080x1888mm

1630x2230x1650mm

748 kg / 828 kg

Advantages:

- Feasible fully automatic solution for average capacity requirements

- Easy to integrate with the production lines directly

- Easy-to-reach spacious design for both maintenance and adjustments

Features:

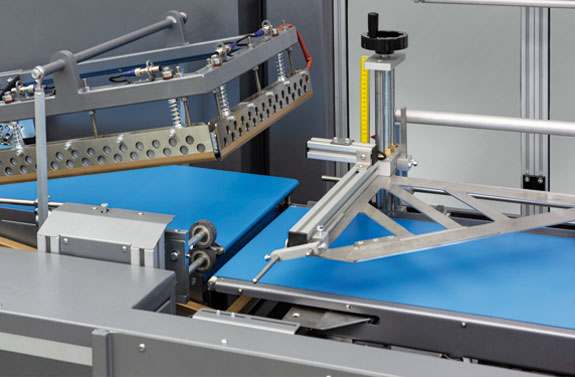

- Automatic length detection by sensor synchronized with encoder control

- User-friendly colorful touch screen operator panel

- Automatic packaging film drive with tension control

- Automatic trim winder with tension control

- Linear sealing ability for various heights by Center-Seal system

- Feeding frequency control by sensor detection and PLC command

- Ability to read instant (or total) realized capacity by counter

- L bar opening limit control by electric servo system

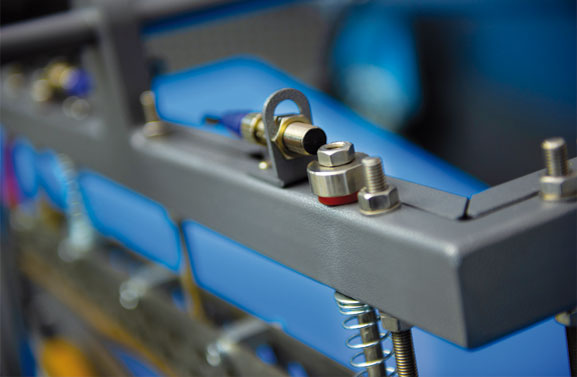

- L bar sealing pressure control system

- Trimmer system with safety sliding window with safety sensors

- Roll nesting unit with CE competible safety doors

- Fixed legs and casters together for both option

- Visual and audio warning signal for film tension variance detection

- Strong needle-wheel frame structure for air discharge perforation

Sealing:

- Fully Teflon coated L shaped hot bar-knife system

- PID controlled sealing temperature inserted by touch panel

- Alternative sealing blade structures for various packaging material

- Product clearance control under seal bar by sensor

Flexibility:

- Easily adjustable for varying product sizes and capacity requirements

- Various language options and adaptable touch keyboard

- Recordable and re-callable product value adjustments

- User friendly designed trim-winder for easy and prompt trim unloading

- Separated film roll cabinet for easy and prompt loading

- On-screen adjustable frontal and hinder gaps

- Feasible fully automatic solution for average capacity requirements

- Easy to integrate with the production lines directly

- Easy-to-reach spacious design for both maintenance and adjustments

Features:

- Automatic length detection by sensor synchronized with encoder control

- User-friendly colorful touch screen operator panel

- Automatic packaging film drive with tension control

- Automatic trim winder with tension control

- Linear sealing ability for various heights by Center-Seal system

- Feeding frequency control by sensor detection and PLC command

- Ability to read instant (or total) realized capacity by counter

- L bar opening limit control by electric servo system

- L bar sealing pressure control system

- Trimmer system with safety sliding window with safety sensors

- Roll nesting unit with CE competible safety doors

- Fixed legs and casters together for both option

- Visual and audio warning signal for film tension variance detection

- Strong needle-wheel frame structure for air discharge perforation

Sealing:

- Fully Teflon coated L shaped hot bar-knife system

- PID controlled sealing temperature inserted by touch panel

- Alternative sealing blade structures for various packaging material

- Product clearance control under seal bar by sensor

Flexibility:

- Easily adjustable for varying product sizes and capacity requirements

- Various language options and adaptable touch keyboard

- Recordable and re-callable product value adjustments

- User friendly designed trim-winder for easy and prompt trim unloading

- Separated film roll cabinet for easy and prompt loading

- On-screen adjustable frontal and hinder gaps

Optional:

- Proper passage of short products by Linking Conveyor

- Printed Film applicability by marker detection sensor and programming

- Ability to use single layer flat film by Center-Folding Unit

- Ability to control additional conveyors by inverters

- Pneumatic sealing with less option to target economic solution

Quality:

- ISO9001 quality standards with the relevant norm’s confirmation

- World-wide brands for all mechanical, electrical and pneumatic components

- CE certifications, complies with the latest CE directives

- One year warranty on non-wearable parts (extendable)

- Manufacturer’s guarantee for spare part stock and after sales support

- Manufacturer’s guarantee for spare part stock availability up to 5 years

- Proper passage of short products by Linking Conveyor

- Printed Film applicability by marker detection sensor and programming

- Ability to use single layer flat film by Center-Folding Unit

- Ability to control additional conveyors by inverters

- Pneumatic sealing with less option to target economic solution

Quality:

- ISO9001 quality standards with the relevant norm’s confirmation

- World-wide brands for all mechanical, electrical and pneumatic components

- CE certifications, complies with the latest CE directives

- One year warranty on non-wearable parts (extendable)

- Manufacturer’s guarantee for spare part stock and after sales support

- Manufacturer’s guarantee for spare part stock availability up to 5 years