Mini & Midi Heat Tunnels

Top motor driven mini and midi size tunnel series

Features:

- Flexibility for the automatic and semiautomatic packaging lines

- Perfect insulation with the dual room principle

- Intelligent heat control with the PID principle controlled system

- Rational control of energy with perfect design of the heating chambers and insulation system.

- Speed control for the conveyor to adjust the time length of heat exposure of packages

- Speed control for the fan speed to adjust the air generation

- Automatic cooling down and power-off system for safe shut-off the entire tunnel

- Adjustable self-rotating life bars to avoid bottom signs of the conveyor bars.

- PE, PVC, POF films applicable and high performance in each types.

- Digital temperature control

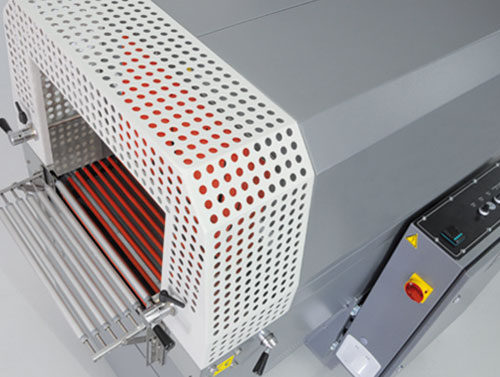

- Top motor for fan and 4 sided air circulation principle

- Adjustable side wings to control the side and bottom air volume

- Equipped casters and legs for easy inhouse moving

- CE marking and conformity to the latest up-to-date directives

- ISO9001-2000 quality assurance - 1 year warranty against production faults

- 5 yıl warranty for the spareparts availability

- Color: Metallic dark Gray (RAL Code: Customized mixture)

- Wire belt, Teflon net belt or modular plastic for high temperature

- Ironing side pressure rollers for PE applications

- PTFE bracelet applied conveyor rods for centering the round shaped products

- Non-heating guides: Special inner guides with temperature control

- Stainless Steel inox body

- At the infeed and discharge points of the tunnels metal protection shields are applied to avoid human contact to high temperature surfaces.

- Conveyors stop automatically during jams to avoid further problems.

- Against high temperature or fire risk, in case of the stop of the conveyor or fan circulation, the heaters are isolated automatically.

- Tunnel fan have been protected with mesh guards and operator hands can not be contacted.

- Heaters have been located in to the closed heating chamber and can not be reached by operator in daily use